We’re accelerating the world’s transition towards a circular economy, by developing next-gen alternatives to natural and synthetic fibers and plastics.

Bloom Labs harnesses the untapped potential of abundant natural waste by-products, to create new high-performance materials that are scalable and commercially viable, yet avoid the use of harmful petrochemicals and resource-intensive processes. Bringing together powerful innovation with cutting-edge science, we’re pioneering game-changing breakthroughs to create a more sustainable future for our planet.

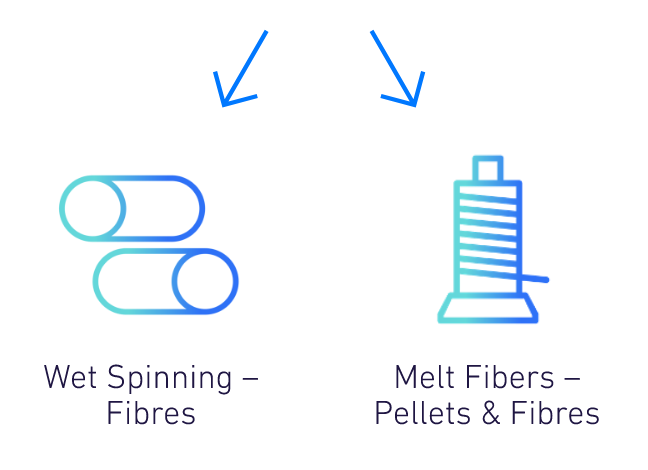

Bloom Labs is pioneering breakthroughs in material science by harnessing the value of natural waste by-products, a protein-rich and globally abundant raw material. Using bio-manufacturing, advanced protein engineering, and molecular biology, our proprietary technology plasticizes waste, regenerating it into uniquely practical and versatile pellets.

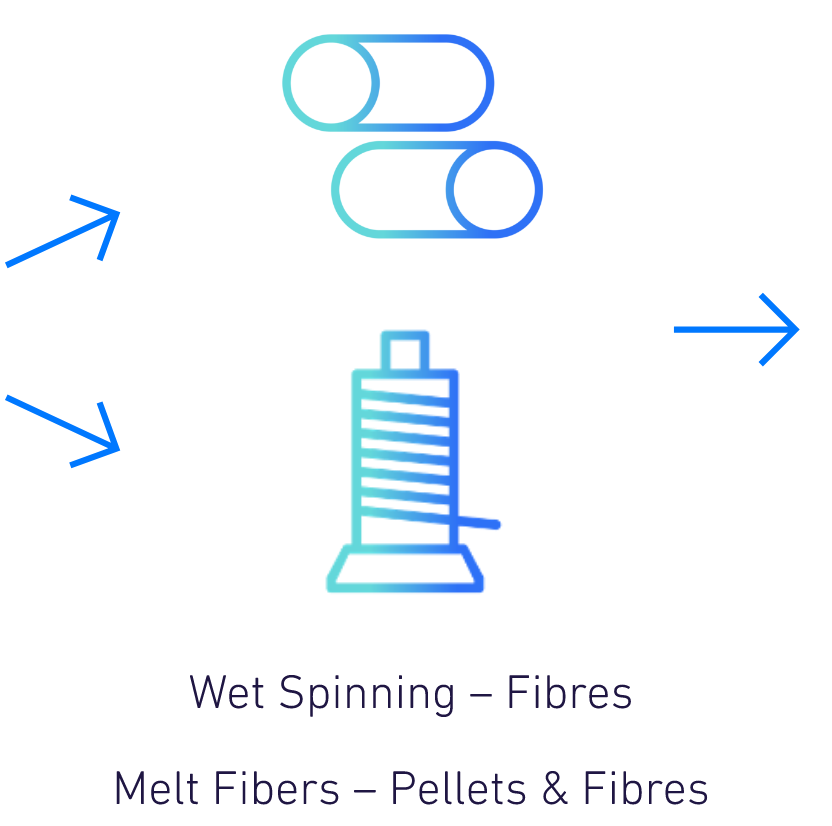

The pellets are spun into high-performance fibers, designed to emulate the properties of current materials – as plush as cotton, as lush as silk, and as functional as polyester. Our easily transportable ‘plug and play’ pellets can be integrated into manufacturers’ production processes, as a scalable raw material without the feedstock risks or environmental impact of petroleum.

Here at the cutting edge of affordable next-gen solutions, our expert team of interdisciplinary scientists includes the inventor of plasticized protein. Together, we’re reimagining material sourcing for multiple sectors, and developing commercially feasible alternatives that will create a future of seamless integration, infinite feedstock, and limitless possibilities.

Two thirds of global fibre production are now synthetic fabrics. Polyester alone has been the most widely produced fibre since the mid-1990s. The problem is these fabrics are fossil fuel-based, shed microplastics, and will never biodegrade. Petrochemical-based fibre production requires 1.3 billion barrels of oil each year – more than Spain’s annual oil consumption.

During their short lives, synthetic garments shed non-biodegradable microplastics when washed, making them the largest source of microplastic pollution in the world’s oceans. Finally, synthetics and polyblend garments will never biodegrade. These imperishable pieces compile in landfills, often in the Global South, or are incinerated, releasing toxic chemicals.

According to Textile Exchange, the global fibre production has doubled in the last twenty years to 113 million tonnes produced in 2021 and is predicted to continue growing to 149 million tonnes in 2030 should business as usual continue. Increasing the use of recycled fibres and next-gen materials is critical for fashion to reduce greenhouse gas emissions, minimize water consumption, halt negative impacts on biodiversity, and manage its ever-increasing post-consumer waste.

While 8.5% of fibres produced in 2021 originated from recycled materials (primarily recycled polyester from PET bottles), less than 1% of fibres were produced by recycling existing textiles. Circularity and material innovation are the key to breaking fashion’s dependence of fossil fuel and mitigating the impacts of our current linear economic systems.